CLG Series Powder Surface Coating Machine

Table of Contents

CLG Series Powder Surface Coating Machine

Capacity: 40-7000kg/h

Max feeding size: Optional

Processing ability: 40-7000kg/h

Range of application: Heavy / light calcium carbonate,kaoline, talcum,wollastonite, mica, white carbon black, zinc oxide,alumina, silicon powder, graphite, magnesium-hydroxide bariumcarb,illite claystone and pyrophylite, hexagonite and etc.

Product Parameter Of CLG Series Powder Surface Coating Machine

|

Model |

Main Power |

Blower Power |

Speed of Shaft |

Capacity |

Weight |

Overall Dimension |

|

CLG-200D |

11 |

2.2 |

5700 |

40-150 |

1 |

3200*600*2200 |

|

CLG-3/300 |

3-18.5 |

5.5 |

4500 |

500-1800 |

3 |

5800*1800*5600 |

|

CLG-3/600 |

3-37 |

15-22 |

2700 |

2000-4000 |

10 |

11200*3100*6200 |

|

CLG-3/900 |

3-75 |

45 |

2000 |

4000-7000 |

20 |

21000*3800*6500 |

Product Introduction Of CLG Series Powder Surface Coating Machine

CLG Series Powder Surface Coating Machine is the inevitable product of the development of modern high technology and new materials. Widely used in non-metallic mineral fillers or pigments such as plastic, rubber, binder and other modern polymer materials, polymer-based composite materials, functional materials and coatings and other industries.

Mineral powders after modification, not only can greatly improve the compatibility of inorganic mineral filler and organic polymer, and improve the interface bonding strength and mechanical strength of reinforced material and its comprehensive performance can be greatly improved powder filler filling capacity, reduce production cost, at the same time, some special physical and chemical properties can be assigned to products.

However, the interface properties of most common non-metallic mineral materials are different from those of organic polymer matrix, and the compatibility is poor. Some mechanical properties of the materials will be reduced by direct or large amount of filling.Therefore, surface modification of inorganic mineral filler is very important.

CLG Series Powder Surface Coating Machine unique design of modified cavity with modified reconciliation function, suitable for all kinds of modified materials, such as the heavy, light calcium carbonate, kaolin, talc, wollastonite, quartz powder, mica, silica, titanium dioxide, zinc oxide, aluminum oxide, magnesium hydroxide and barium sulfate, illite and pyrophyllite, tremolite etc, all have very good effect on the surface modification.

Working Principle Of CLG Series Powder Surface Coating Machine

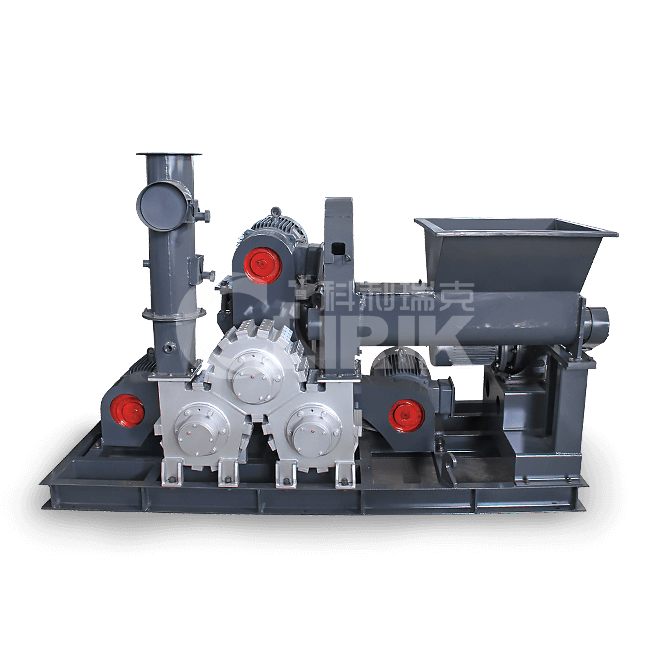

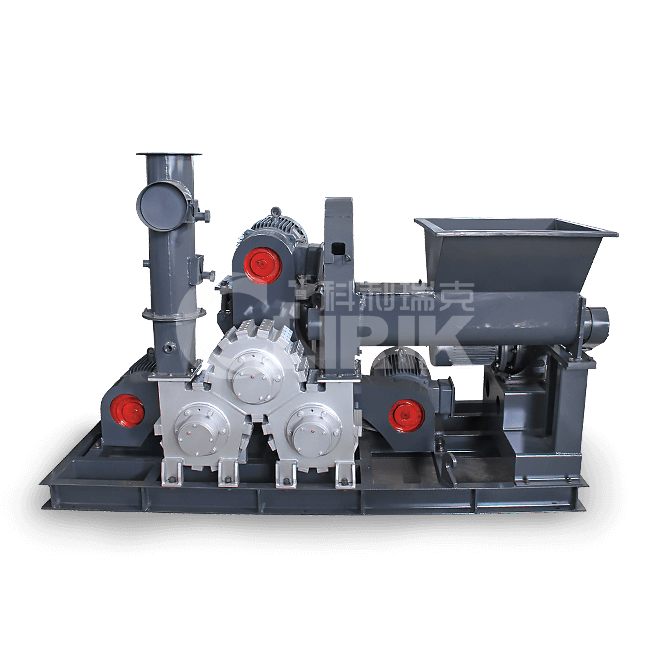

The structure composition of CLG Series Powder Surface Coating Machine:

1, Hopper: the material from the bin directly into the hopper, the moisture content of the material should be less than 0.5%.

2, Feeding device: double screw feeding, speed adjustable, can ensure the stability of material flow.

3, Temperature control dosing system: temperature control, can be set at will the melting temperature of agents, suitable for all kinds of solid liquid form of modified agents.

4, Modification host: modification host is composed of three product shape modification cylinder, compact structure, high modification efficiency, stable and reliable operation.

Working principle of CLG series powder surface coating machine:

The powder raw material is sent to the atomizing room above the main machine through the feeding conveying system. In the conveying process, the powder is heated and dried by the special heating device of the feeding conveyor. At the same time, the solid modifier is also heated and melted to the liquid state in the special heating container after being sent to the atomizing room through the conveying pipeline.

The atomizing room is provided with two groups of nozzles, in which the group has four nozzles distributed in different positions on the wall of the atomizing room. Its role is to blow the powder material sent by the conveying system into mist. At this point, the raw material and the modification machine form mist. Due to the effect of two groups of nozzles from different directions of the jet flow, to be fully mixed, that is, into the host.

The main machine is composed of a high-speed rotating spindle, agitator bar, impact hammer and so on. The atomized material entering the main machine is affected by impact, friction and shear under the high-speed agitation of the agitator bar, so that the powder particles and the modifier are fully contacted and mixed. At this time, the powder material is fully coated and modified.

Performance Characteristics of CLG Series Powder Surface Coating Machine

1.The CLG series powder surface coating machine can continuously run production, large capacity, suitable for various scales of industrial production.

2.The utilization rate of the modified agent is high, the dosage is small, the powder coating rate and activation index is high, and the energy consumption is low.

3.The CLG series powder surface coating machine has both modification and breaking function, suitable for all kinds of fineness of the material, the false specific gravity of small, large bulk density ratio of the material such as white carbon black, mica powder, talc powder has a unique modification and activation effect.

4.Powder and reagent high-speed gas-solid eddy current mixing operation, high modification efficiency, basically does not destroy the original powder shape.

5.Material negative pressure operation, good sealing, dust does not leak, basic pollution-free, good operating environment, low labor intensity.

6.The completion of hot and cold machines, no separate heating and cooling system, simplify the operation.

7.Independent fluid, non-fluid dosing system, continuous stability and uniformity.

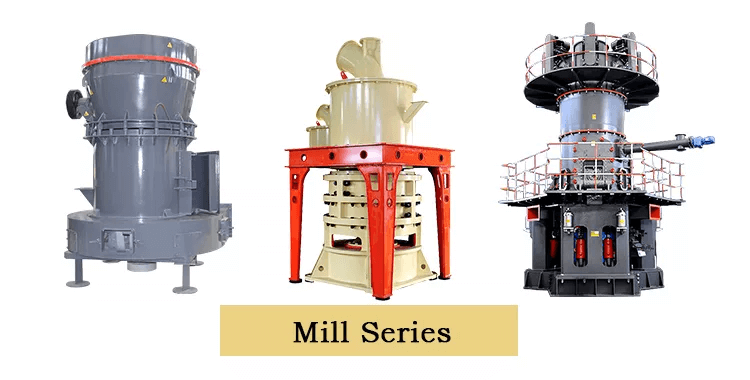

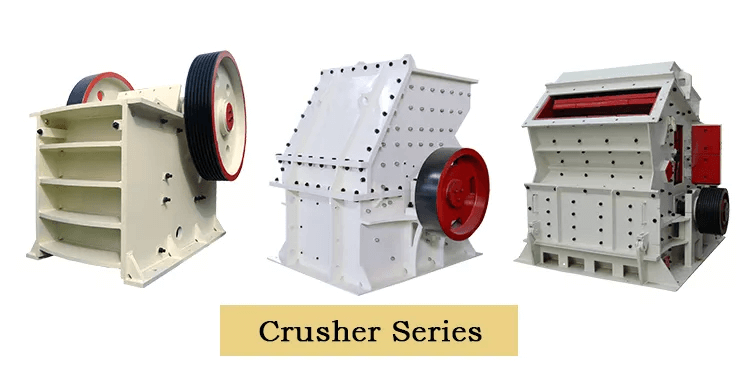

Other Products Offered

FAQ

Q: Are you a middle man or manufacturer?

A: Our Shanghai Clirik Machinery is a professional mining equipment manufacturer.

Q: How to get in touch with you?

A: You can leave your inquiry below this product, or you can call us 86-135 1213 7665

Q: Where is your company?

A: We are in PuDong new area, HeQing twon, FuQing road, No. 19, Shanghai, China.

High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.