Gypsum Powder High Pressure Suspension Grinding Mill

Table of Contents

- 1 Product Description Of Gypsum Powder High Pressure Suspension Grinding Mill

- 2 Working Principle Of Gypsum Powder High Pressure Suspension Grinding Mill

- 3 Product Advantages Of Gypsum Powder High Pressure Suspension Grinding Mill

- 4 Product Parameter Of Gypsum Powder High Pressure Suspension Grinding Mill

- 5 Customer Cases Of Gypsum Powder High Pressure Suspension Grinding Mill

- 6 Other Products offered

- 7 Introduction Manufacturer of Gypsum Powder High Pressure Suspension Grinding Mill

- 8 FAQ

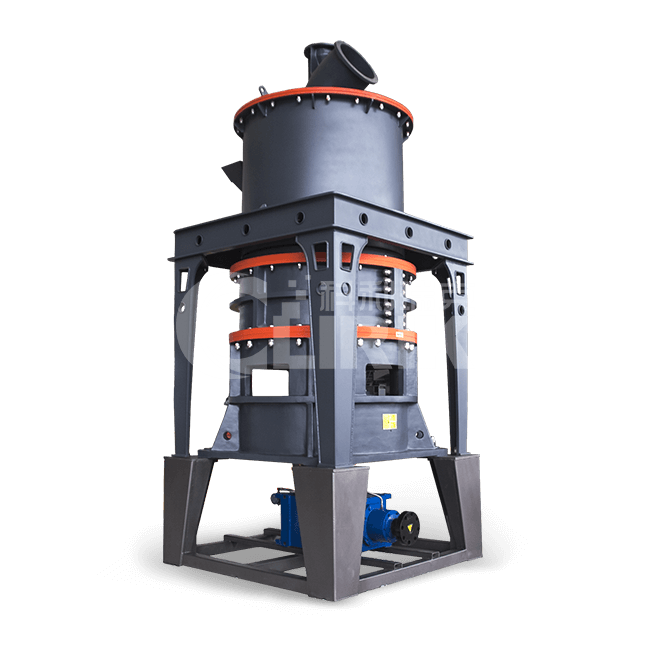

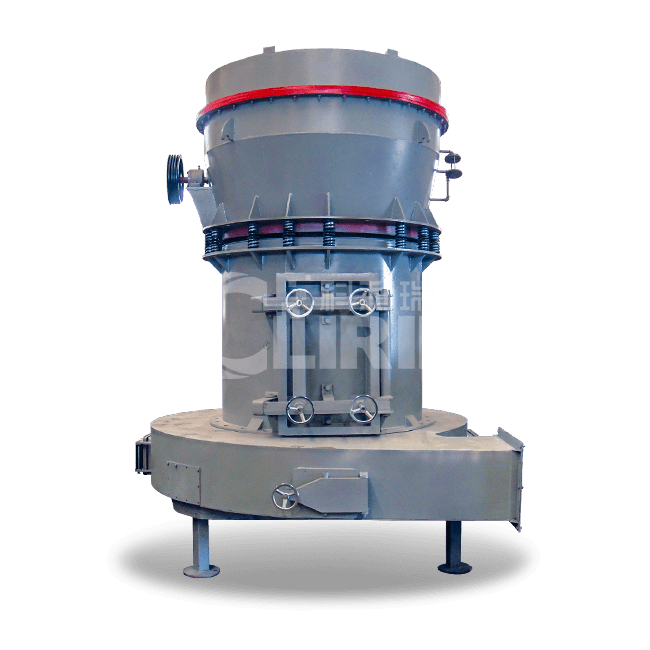

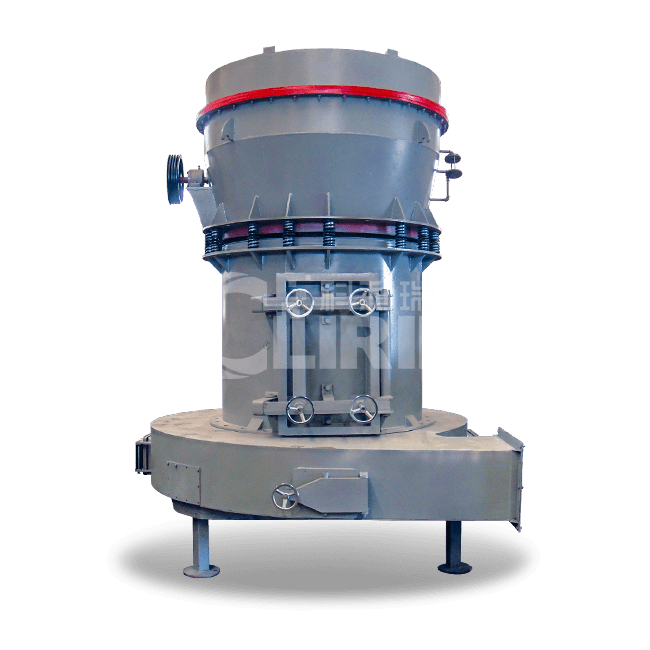

Gypsum Powder High Pressure Suspension Grinding Mill

Model: YGM series

Brand: Clirik

Fineness Size : 50-325 mesh

Capacity : 1-25 t/h

Use Range : Gypsum,Calcium Carbonate,Dolomite,Carbon Black,Glass,Kaolin,Marble ,Glass…

Application : Mining, Chemiscal, Transport and many other different areas.

Product Description Of Gypsum Powder High Pressure Suspension Grinding Mill

Gypsum powder high pressure suspension grinding mill is one of the main products of our company. And as one of the biggest production bases in China, our company has produced Gypsum powder high pressure suspension grinding mill with better WOM in the Raymond grinding equipment market.

Gypsum powder high pressure suspension grinding mill is applicable to the grinding and processing of more than 280 kinds of non-flammable and non-explosive materials with hardness less than 6 and humidity less than 6% in mining, construction, chemical industry and metallurgy, such as gypsum,barite, calcite, feldspar, talcum, marble, limestone, clay, glass. The fineness of the finished product can be adjusted from 50 mesh to 325 mesh according to requirements.

Working Principle Of Gypsum Powder High Pressure Suspension Grinding Mill

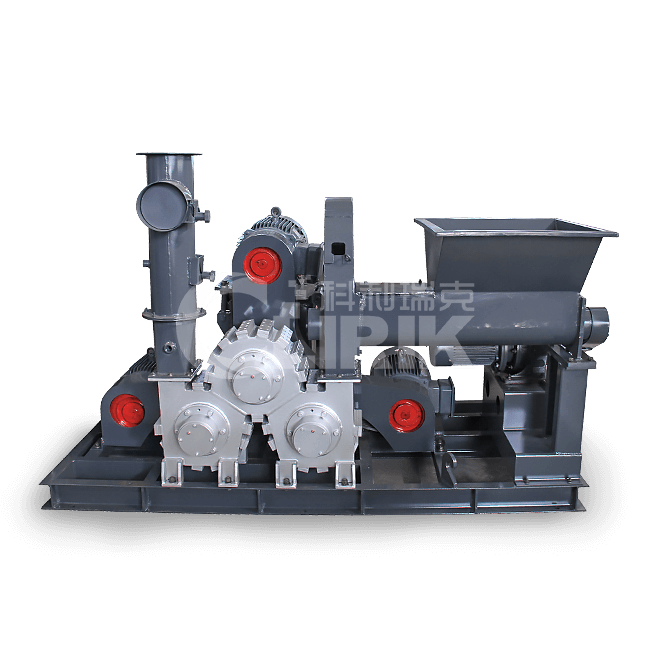

The standard configuration of Gypsum Powder High Pressure Suspension Grinding Mill consists of main unit, reducer, powder classifier, cyclone powder collector, dust cleaner, blower, control cabinet motor and pipes. The optional accessories include a crusher, bucket elevator, feeder.

Product Advantages Of Gypsum Powder High Pressure Suspension Grinding Mill

1.High pressure spring design

2.Smoothly vibration reduces design

3.Convenient vane adjust design

4.The machine has a strong material applicability, which suits many kinds of material whose Moh’s hardness is less than 6.

5.Grinding device adopts superimposed seal, sealed performance is good.

Product Parameter Of Gypsum Powder High Pressure Suspension Grinding Mill

| Model | Roller | Ring | Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*1050 |

Customer Cases Of Gypsum Powder High Pressure Suspension Grinding Mill

The following is the customer case site of Gypsum Powder High Pressure Suspension Grinding Mill:

If you want to know more information, you can consult our online customer service or leave your email or Whatsapp. Our sales manager will reply to you with a detailed product, case list information and product quotation list within one hour.

Ethiopia Case

Indonesian Case

Ethiopia gypsum ultrafine powder production line used Clirik high-cost performance gypsum powder high pressure suspension grinding mill.

This customer case uses gypsum powder high pressure suspension grinding mill industrial mill to grind talc into a fine powder (325 mesh).

Myanmar Case

Pakistan Case

The Myanmar customer needs to produce 125 mesh calcite powder used by Clirik gypsum powder high pressure suspension grinding mill.

This customer case uses YGM Series gypsum powder high pressure suspension grinding mill to grind calcium carbonate into a fine powder (300 mesh).

Other Products offered

If our YGM series Gypsum Powder High Pressure Suspension Grinding Mill does not meet your needs, we have other series gypsum powder mills for you to choose from. For more information, please contact us and our sales manager will send you a detailed product introduction and quotation list.

Introduction Manufacturer of Gypsum Powder High Pressure Suspension Grinding Mill

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai China as a professional enterprise, which specializes in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production lines, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products cover micro powder grinding mill, high pressure grinding mill, European coarse powder mill, hammer crusher, jaw crusher, screw conveyor,bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on.

In particular, we independently developed HGM micro powder grinding mill, which are not only renowned in the domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia,Southeast Asia, Oceania, and America, etc.We still insist on communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always on the At home and abroad front.

Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment, optimized process configuration and a full range of technical support. Therefore, we always follow your steps, pursue your value and achieve your benefit.

FAQ

- Previous: CLG Series Powder Surface Coating Machine

- Next: Gypsum Powder Ball Mill