Gypsum Powder Ball Mill

Table of Contents

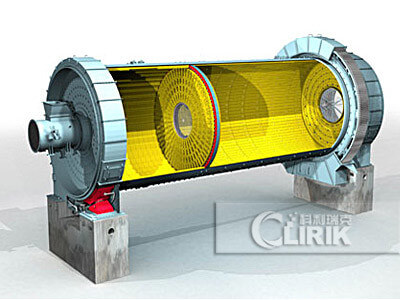

Product Introduction Of Gypsum Powder Ball Mill

Gypsum powder ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Gypsum Powder Ball Mill

Capacity: 200 t/h

Max feeding size: 25 mm

Processing ability: 200 t/h

Range of application: Gypsum, limestone, calcium carbonate, clay, dolomite and other minerals which can be used in cement powder making.

Working Principle Of Gypsum Powder Ball Mill

Gypsum powder ball mill machine changes the intrinsic grinding mill structure. Its body and ground plank are an integral whole. So when fixing, it can be lowered on a plane surface once only. Use double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30%. The intrinsic grille pattern forcing evacuation is instead by over fall pattern controlling one. This can improve the milling of the granule and the quantity dealt with is reduced by 15-20%.

Gypsum powder ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Product Features Of Gypsum Powder Ball Mill

1. Strong adaptability of materials.

Gypsum powder ball mill can grind all kinds of ore materials, complete the processing of different materials with different fineness, to meet the needs of various production capacity, the output per hour from hundreds of grams to 200 ~ 300 tons, especially continuous production, high production capacity, can meet the needs of modern large-scale industrial production.

2. Broken than big.

Up to 300 or more, the fineness of the product is easy to adjust, the particle size of the product is uniform, and the stirring effect is good.

3. Strong adaptability.

It can be operated under a variety of different conditions. Dry production, wet production, dry production and powder can be operated simultaneously.

4. Simple structure.

The gypsum powder ball mill is composed of feed, discharge, rotary, transmission (reducer, small transmission gear, motor, electric control) and other main components. Simple operation, convenient maintenance and management, can run continuously for a long time.

5. Environmentally friendly.

Gypsum powder ball mill has a good sealing device to prevent dust from flying.

Product Parameter Of Gypsum Powder Ball Mill

|

Model |

Rotary speed(r/min) |

weight(t) |

Input size(mm) |

Discharge size(mm) |

Capacity(t/h) |

Motor power (kw) |

Weight (t) |

|

Ф900×1800 |

39 |

1.5 |

≤20 |

0.075-0.89 |

0.8-2 |

18.5 |

4.6 |

|

Ф900×1800 |

39 |

2.7 |

≤20 |

0.075-0.89 |

1-4 |

22 |

5.6 |

|

Ф1200×3000 |

36 |

3.5 |

≤25 |

0.074-0.4 |

1.6-5 |

37 |

12.8 |

|

Ф1200×4500 |

32 |

5 |

≤25 |

0.074-0.4 |

1.6-5.8 |

55 |

13.8 |

|

Ф1500×3000 |

27 |

7.5 |

≤25 |

0.074-0.4 |

2-5 |

75 |

15.6 |

|

Ф1500×5700 |

28 |

12 |

≤25 |

0.074-0.4 |

3.5-6 |

130 |

24.7 |

|

Ф1830×3000 |

25 |

11 |

≤25 |

0.074-0.4 |

4-10 |

130 |

28 |

|

Ф1830×6400 |

24 |

21 |

≤25 |

0.074-0.4 |

7-16 |

210 |

34 |

|

Ф1830×7000 |

24 |

23 |

≤25 |

0.074-0.4 |

8-18 |

245 |

36 |

|

Ф2100×3600 |

23 |

19 |

≤25 |

0.074-0.4 |

10-36 |

210 |

46 |

|

Ф2200×4500 |

21 |

27 |

≤25 |

0.074-0.4 |

12-23 |

280 |

48.5 |

|

Ф2200×6500 |

21 |

35 |

≤25 |

0.074-0.4 |

14-26 |

380 |

52.8 |

|

Ф2200×7000 |

21 |

35 |

≤25 |

0.074-0.4 |

15-28 |

380 |

54 |

|

Ф2200×7500 |

21 |

35 |

≤25 |

0.074-0.4 |

15-30 |

380 |

56 |

|

Ф2400×4500 |

21 |

30 |

≤25 |

0.074-0.4 |

18-45 |

320 |

65 |

|

Ф2400×8000 |

20 |

36 |

≤25 |

0.074-0.4 |

20-48 |

410 |

81 |

|

Ф2700×3600 |

21 |

39 |

≤25 |

0.074-0.4 |

19-75 |

400 |

83 |

|

Ф2700×4000 |

20 |

40 |

≤25 |

0.074-0.4 |

20-78 |

400 |

85 |

|

Ф2700×4500 |

20 |

48 |

≤25 |

0.074-0.4 |

22-85 |

430 |

89 |

|

Ф3200×4500 |

18 |

65 |

≤25 |

0.074-0.4 |

29-140 |

800 |

137 |

|

Ф3200×5400 |

18 |

81.6 |

≤25 |

0.074-0.4 |

30-180 |

800-1000 |

146 |

|

Ф3600×4500 |

17 |

88 |

≤25 |

0.074-0.4 |

35-210 |

1000 |

190 |

|

Ф3600×6000 |

17 |

117 |

≤25 |

0.074-0.4 |

38-240 |

1250-1500 |

220 |

|

Ф3600×8500 |

17 |

144 |

≤25 |

0.074-0.4 |

45-260 |

1800 |

260 |

Introduction Manufacturer of Gypsum Powder Ball Mill

Company Information

Shanghai Clirik Machinery Co., Ltd. is located in Pudong New District, Shanghai, China, which is specialing in manufacturing grinding mills, Raymond mills, crushers, ball mill and other associate accessories with decades of experience. We have a strong and professional technical and sales team. Customers’ satisfaction is our final and forever pursuing.

Our Services

Pre-sale service:

1. Clirik provides a variety of mining equipment for you to choose from.

2. Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3. Clirik customizes the logo and color of the grinding equipment according to your company image.

4. Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and uses videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for grinding equipment.

Our Certificate

Our mining grinding equipment has won a number of special train certificates, you can rest assured to buy.

FAQ

1. What advantages does your gypsum powder ball mill have?

The main advantage of our gypsum powder ball mill over other kinds of mills is that you can grind a friable or crystalline material to fine average particle size and classify in a very narrow particle size range at the same time.

2. What particle size range does your gypsum powder ball mill produce?

Typically the Clirik gypsum powder ball mill will grind friable or crystalline materials down to the 0.075 -0.4/0.89 mm average particle size range. Particles larger than 10 microns are generally hard-to-fracture polymers such as toner compounds or hard waxes, and some organic materials, but if a larger size is wanted, many products can be ground larger than 10 microns by reducing power to the mill or by increasing the rate of feed. Some products are simply polished to remove sharp edges by running at elevated feed rates with low grinding pressure, a process that changes how the material compacts.