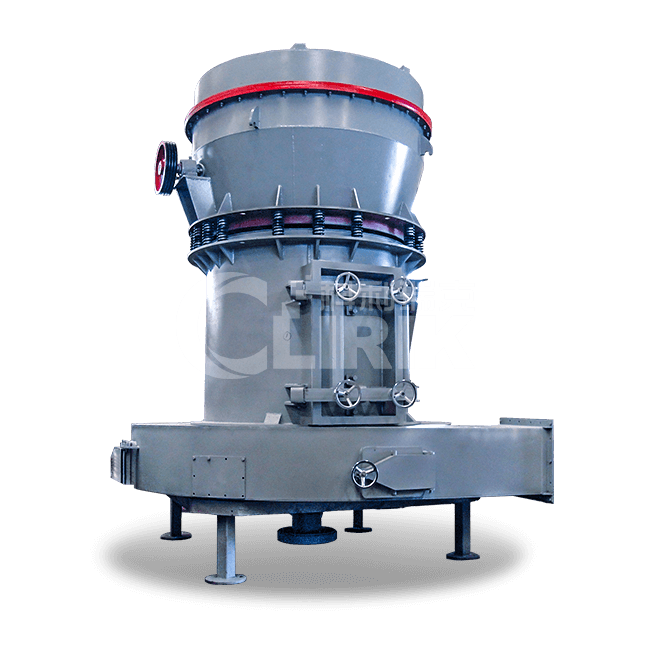

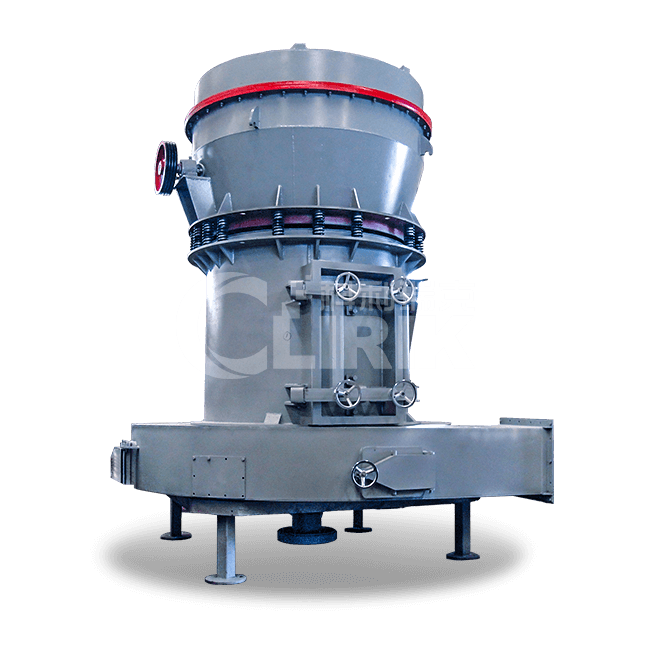

Gypsum Powder Raymond Mill

Table of Contents

Gypsum Powder Raymond Mill

Model: YGM series

Brand: Clirik

Fineness Size : 50-325 mesh

Capacity : 1-25 t/h

Use Range :Calcium Carbonate、Dolomite、Gypsum、Carbon Black、Glass、.Gypsum、Kaolin、 Marble …

Application : Mining, Chemiscal, Transport and many other different areas.

Product Parameter Of Gypsum Powder Raymond Mill

| Model | Roller | Ring | Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*1050 |

Product Introduction of Gypsum Powder Raymond Mill

Gypsum powder raymond mill also called gypsum powder grinding mill,Widely used in metallurgy, building materials, chemical industry, mining and other fields of mineral materials grinding processing, suitable for processing mohs hardness below 6, humidity below 6% of all kinds of non-flammable and explosive minerals, Such as gypsum, talc, calcite, limestone, marble, potassium feldspar, barite, dolomite, granite, kaolin, bentonite, medical stone, bauxite, iron oxide red, iron ore, etc.,

Working Principle Of Gypsum Powder Raymond Mill

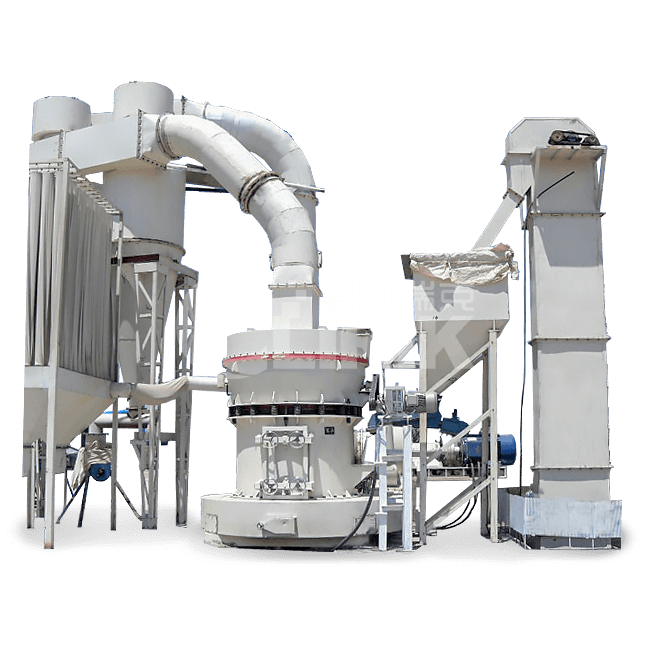

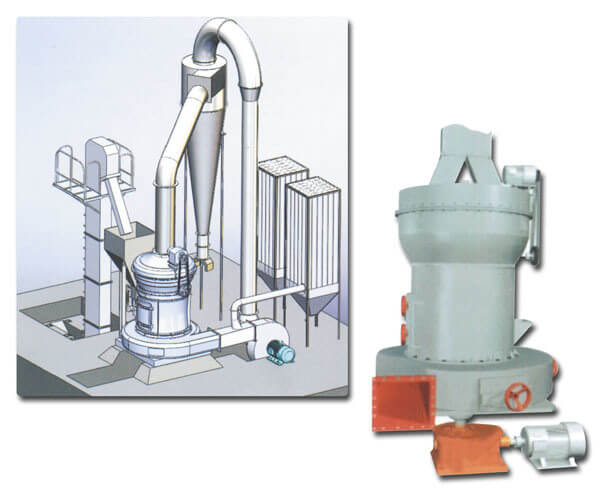

Gypsum powder Raymond mill equipment is predominantly composed of host, powder separator, fan, jaw crusher, Bucket Elevator, ibrating Feeder, storage bin, Pulse Bag Filter, pipe device, cyclone collector, electric control cabinet, motor and so on.

Gypsum Powder Raymond Mill grinds big materials, it needs to use a crusher to grind the materials to the required particle sizes, and carried by bucket elevator to the storage hopper, and are fed evenly and continuously by vibrating feeder into the main unit for grinding. The grinded powder are carried by the airflow from the blower to the classifier to be classified, the particles which meet the fineness enter cyclone collector through pipe, and are separated and collected there. They are discharged at the discharging valve to become finished products; The airflow is sucked to the blower by return pipe on the top of cyclone collector. The whole airflow system is a sealed circulation, and is circulated under positive and negative air pressure.

Product Advantages Of Gypsum Powder Raymon Mill

1.Gypsum powder raymon mill is mature and stable.

Nearly 30 years of experience in grinding and designing different materials, mature transformation of gypsum powder raymon mill.

2.High efficiency, Large output.

Gypsum powder raymon mill breaking through the bottleneck of traditional pendulum mill production capacity, enjoy the advantages of large single production capacity at home and abroad, single processing capacity up to 50T/H, under the same power, the output is 20% higher than the traditional R Raymond mill, 30% higher than the ball mill.

3.Reliable technology and low operating cost.

New technology, China’s national patent products, with technical innovation to create a three-dimensional structure, small footprint, strong system, from raw material rough processing, transportation, milling, to the final packaging, can become an independent production system gypsum powder Raymond mill.

Special grinding roller and grinding ring structure design, improve grinding efficiency, use cost reduction. The volute adopts the layout of no resistance and the same resistance, which greatly reduces the power and energy loss caused by the system energy consumption.

4.Multi-purpose, Investment economy

Without replacing any parts, one device is used for different materials and different finished particle size requirements.

Under the same output, the investment amount is only half of the ball mill, and the floor area is only one third of 4R Raymond mill. The infrastructure construction cost of the factory is low, the investment is economical, the capital recovery is quick, and the profit is quick.

5.Provide overall solutions.

Proprietary empirical equipment, before the project to provide users with the possibility of testing machine research, to provide users with crushing, drying, grinding, screening, packaging design, supply, construction, service and other aspects of the solution.

6.Energy conservation and environmental protection.

Gypsum powder Raymond mill is equipped with a special dust collector device, dust removal effect of 99.99% or more, basically achieve dust-free workshop operation. Low operating noise, machine vibration is tiny, the noise is 20-30 decibels lower than the ball mill.

Maintenance Of Gypsum Powder Raymond Mill

1, Gypsum powder Raymond mill in the process of use, there should be fixed personnel responsible for monitoring, operators must have a certain technical level. Before the installation of the mill, the operator must carry out the necessary technical training, so that they can understand the principle and performance of the mill and be familiar with the operating procedures.

2.In order to guarantee the normal operation of Gypsum powder Raymond mill, “Equipment maintenance safety operation System” should be formulated to ensure the long-term safe operation of the mill. At the same time, necessary maintenance tools, grease and corresponding accessories should be provided.

3.Gypsum powder Raymond mill after operating for a period of time, should be repaired, while the roller grinding ring shovel knife and other wearing parts for maintenance and replacement treatment, the roller device before and after using the connection bolts and nuts should be carefully checked to see whether there is loosening phenomenon, whether the lubrication grease is sufficiently.

4.When the roller is replaced after the service time of the roller grinding device exceeds 500 hours, the rolling bearings in the roller sleeve must be cleaned and the harmed parts should be replaced in time. The refueling tool can be manually added oil pump and butter gun.