Gypsum Powder Ultrafine Vertical Grinding Mill

Table of Contents

- 1 Product Introduction Of Gypsum Powder Ultrafine Vertical Grinding Mill

- 2 Product Parameter Of Gypsum Powder Ultrafine Vertical Grinding Mill

- 3 Product Application Of Gypsum Powder Ultrafine Vertical Grinding Mill

- 4 Working Principle Of Gypsum Powder Ultrafine Vertical Grinding Mill

- 5 Feature and Advantages Of Gypsum Powder Ultrafine Vertical Grinding Mill

- 6 Other Gypsum Powder Grinding Equipment Is Recommended

- 7 FAQ

Gypsum Powder Ultrafine Vertical Grinding Mill

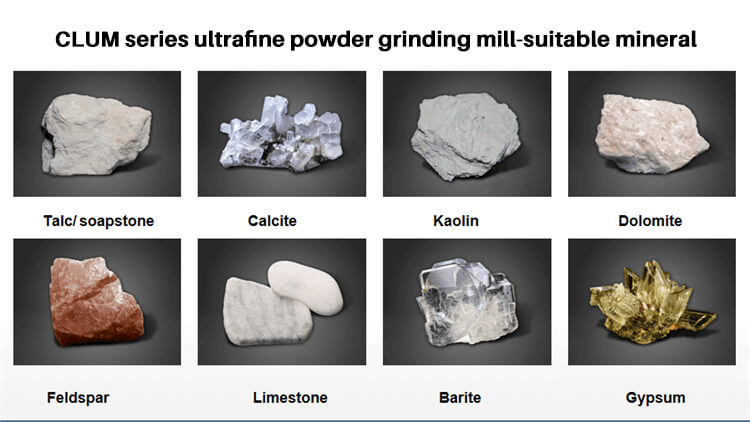

Model: CLUM Series

Brand: Clirik

Fineness Size : 400-3000 mesh

Capacity : 3 – 45t/h

Use Range :Gypsum,Calcium Carbonate,Dolomite,Carbon Black,Limestone,Kaolin,Marble …

Application : Mining, Chemiscal, Transport and many other different areas.

Product Introduction Of Gypsum Powder Ultrafine Vertical Grinding Mill

Gypsum powder ultrafine vertical grinding mill is a large high-fine vertical mill independently developed by Clirik Company to meet the development needs of the non-metallic mining industry. It is studied on the basis of the European, Taiwan vertical mill, and has broken through the problems of low capacity and high energy consumption of the traditional mill. Clirik Vertical Roller Grinding Mill adopts reliable structure and reasonable process flow, integrated with drying, milling, classifier, elevator. More in line with the demand of the grinding market. It has become an ideal equipment for large-scale production of ultrafine powder.

Product Parameter Of Gypsum Powder Ultrafine Vertical Grinding Mill

| Model | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 5 | 7 | 7 |

| Power of classifier(Kw) | 5X15 | 7X15 | 7X(15~18.5) |

| Main unit power (Kw) | 250 | 315 | 355 |

| Blower power(Kw) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=34% output(t/h) |

11-14 | 13-17 | 15-19 |

| Less than 2μm=46% output(t/h) |

7-8 | 9-10 | 11-12 |

| Less than 2μm=60% output(t/h) |

3-4 | / | / |

| Material: based on gypsum Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

Product Application Of Gypsum Powder Ultrafine Vertical Grinding Mill

Gypsum powder ultrafine vertical grinding mill is suitable for huge capacity producing, widely used in grinding non-flammable and non-explosive materials under 7(the Moh’s hardness), such as gypsum, quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Working Principle Of Gypsum Powder Ultrafine Vertical Grinding Mill

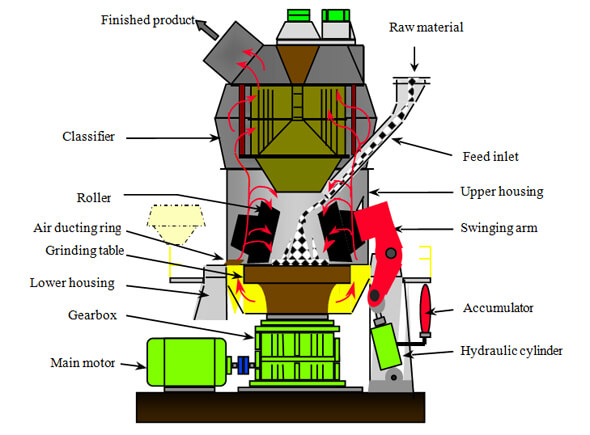

Gypsum Powder ultrafine Vertical Grinding Mill is mainly composed of the main machine, feeder, classifier, blower, pipe device, storage hopper, electric control system, collection system, etc.

Gypsum Powder Ultrafine Vertical Grinding Mill The motor drives the reducer to drive the grinding disc to rotate, and the materials to be ground are sent to the rotating center of the grinding disc by the air-locked feeding equipment. Under the action of centrifugal force, the materials move to the surrounding of the grinding disc and enter the grinding roller. Under the action of roller pressure, the material is crushed by extrusion, grinding and shearing.

At the same time, the wind is ejected uniformly from the air ring around the mill disc at a high speed, and the ground material is blown up by the high-speed air flow at the air ring, and the coarse-grained material is blown back to the mill disc for grinding again.

The fine powder is carried by the wind to the grading machine for grading, and the qualified fine powder is taken out of the mill with the air flow and collected by the dust collecting equipment. The unqualified coarse powder falls to the grinding plate again under the action of the blades of the grading machine, and is ground again together with the newly fed material, so as to complete the whole process of grinding operation.

When the iron and other debris mixed with the material moves to the edge of the mill plate with the material, it cannot be blown up by the wind due to its large weight, and falls into the lower chamber of the mill and is scraped into the slag discharge mouth by the scraper, which can effectively ensure the quality of the finished product.

Feature and Advantages Of Gypsum Powder Ultrafine Vertical Grinding Mill

Feature

1.Secondary grading system of gypsum powder ultrafine vertical grinding mill

The secondary classification system consists of super fine classifier, fan, dust collector, bin, screw conveyor, pipe and other equipment. Superfine classifier is its core equipment.

The gypsum powder ultrafine vertical mill is equipped with a secondary air separation grading system, high efficiency of powder selection, can effectively separate coarse powder and fine powder, the fineness of separation can be up to 3μm, to obtain a variety of qualified products.

2.Characteristics of secondary grading of gypsum powder ultrafine vertical grinding mill

High grading efficiency The classifier and fan are controlled by frequency conversion speed regulation. By adjusting the speed of the impeller of the classifier and fan, the fineness of finished products with different specifications can be obtained quickly and stably, and the classification efficiency is high. Powder separator,high efficiency, energy saving powder separator. Single head and multi head separator can be used, the fineness of the finished product can be adjusted.

Advantage

1.Good quality of finished products

Finished products have high whiteness, fine particle size, narrow particle size distribution, and good particle sphericity. The fineness D97 of the finished powder can reach 3000 meshes, and the content of 2μm can reach up to 60%.

2.High grinding efficiency

Save 20~30% power consumption compared with the ball mill.

3.Strong drying capacity

Dry and grind raw materials with moisture content as much as 15%.

4.Multifunction

crushing, drying, grinding, separating, and conveying.

5.Low noises and little dust

No direct contact between the grinding rollers and grinding disc, so metallic impact is avoided, and its noises are 20~25 decibels lower. Totally closed negative pressure operation has been employed by this vertical grinding mill, so there is little dust during the operation.

6.Low wear rate and little metallic pollution

It’s metal wear is only 5~10g/t. Low wear rate and little metallic pollution: its metal wear is only 5~10g/t.

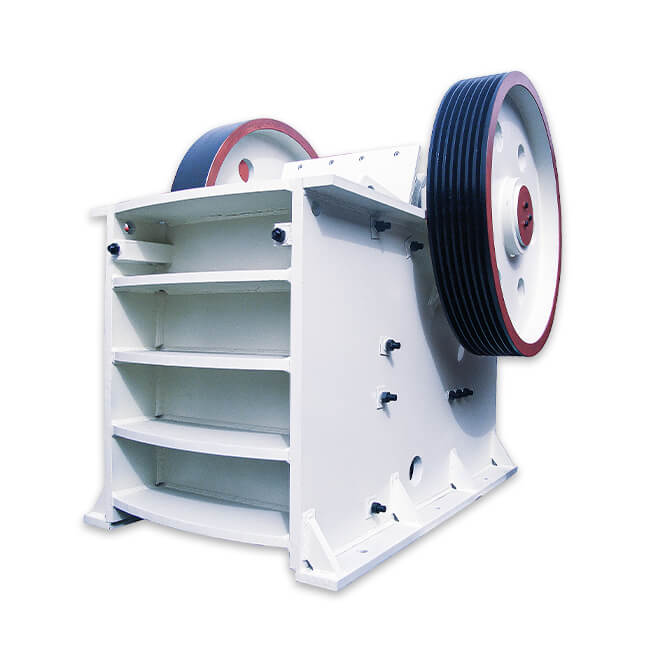

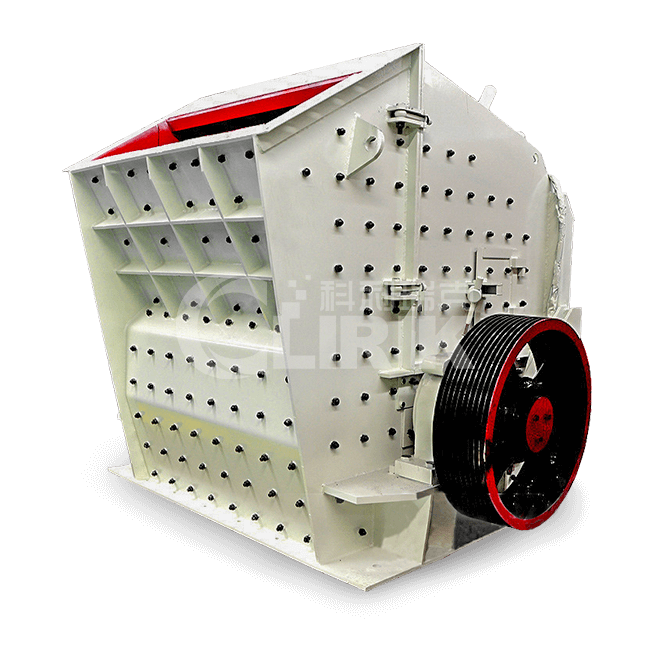

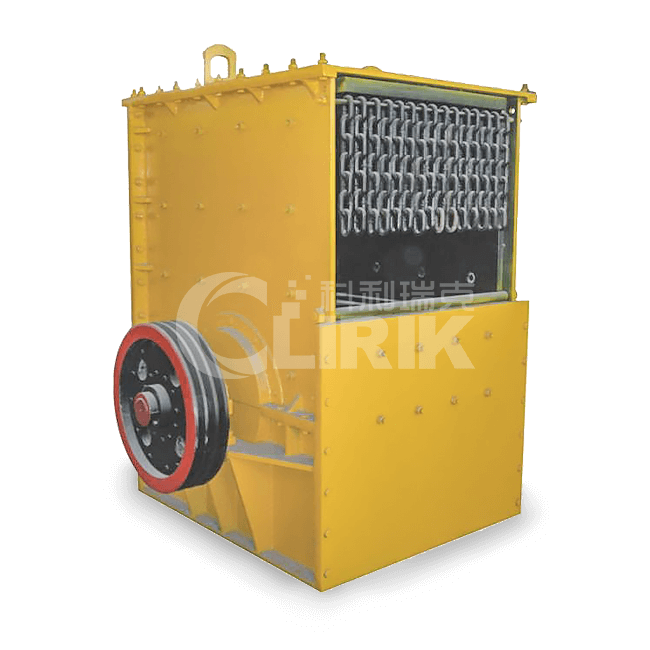

Other Gypsum Powder Grinding Equipment Is Recommended

If our CLUM serirs gypsum powder ultrafine vertical grinding mill does not meet your needs, we have other series of mills for you to choose from. For more information, please contact us and our sales manager will send you a detailed product introduction and quotation list.

FAQ

Because there are 3 different kinds of gypsum powder ultrafine vertical grinding mills, so our gypsum powder ultrafine vertical grinding mill unit has different prices, I need to ask you for some details for sending you the more suitable quotation:

1. Which kind of material are you going to grind?

(Gypsum;Basalt; Dolomite; Calcite; Quartz;Barite; Feldspar ;Bentonite; Vermiculite;Granite; Coal; Slag; Pebble; Others .)

2.What’s the production capacity you want? How many tons or cubic meters per hour?

(> 100 TPH > 50 TPH > 30 TPH > 10 TPH > 1 TPH < 1 TPH)

3. What’s the granularity of the final products you need?

(in milimeter, micron or mesh)

4.What’s the max input size of the material?

(In inch, centimeter or millimeter)

- Previous: Gypsum Powder Raymond Mill

- Next: PY Series Gypsum Powder Cone Crusher