Raymond Roller Grinding Mill Machine

Table of Contents

Raymond roller grinding mill machine customer case display

Processing Equipment : Raymond roller grinding mill machine

Processing Materials : Gypsum

Maxing Feeding Size: 40 mm

Ouput Size: 0.613-0.033 micron (40-400 mesh)

Capacity: 1-25 t/h, D97 <325 mesh,2μm <10%

What is Raymond roller grinding mill machine?

Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, 3R/4R/5R/6R Roller Mill and Raymond Mill Machine. It is widely applied in ore materials grinding.

Raymond mill is the key equipment of powder production line. It is suitable for powder processing below 400 mesh. It is an ideal equipment for powder processing plants with small and medium output.

Appliction of Raymond roller grinding mill machine

Raymond roller grinding mill machine is to grind non-flammable and non-explosive materials in the fields of building materials, mining, metallurgies and chemical industry with hardness less than 9.3 in Moh’s scale and humidity less than 6 percent. Examples of the materials are: quartz, feldspar, barite, fluorite, dolomite, garnet, bauxite, zircon, marble, calcite, iron ore, rock phosphate, coal, slag and so on(400 kinds of material).

Raymond Roller Grinding Mill Machine after years of practice and continuous improvement, its structure has become more and more perfect. Therefore, it is widely used in the grinding and processing of mineral products and materials in metallurgy, building materials, chemical industry, mining and other fields.

Parameter of Raymond Roller Grinding Mill Machine

| Model | Roller | Ring | Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*1050 |

How does the Raymond roller grinding mill machine work?

Raymond Roller Grinding Mill Machine Structure

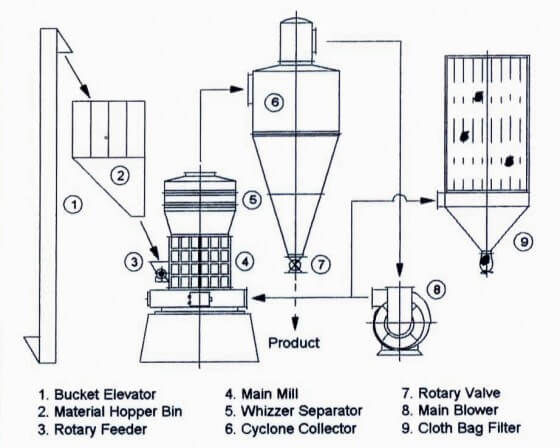

Raymond mill is composed of grinding unit, reduction gear, classifier, pipe line, blower, dust collector, jaw crusher, bucket elevator, electromagnetic feeder and electronic control system.

Working Principle of Raymond Roller Grinding Mill Machine

Raymond roller grinding mill machine grinds big materials, it needs to use a crusher to grind the materials to the required particle sizes, and carried by bucket elevator to the storage hopper, and are fed evenly and continuously by vibrating feeder into the main unit for grinding. The grinded powder are carried by the airflow from the blower to the classifier to be classified, the particles which meet the fineness enter cyclone collector through pipe, and are separated and collected there. They are discharged at the discharging valve to become finished products; The airflow is sucked to the blower by return pipe on the top of cyclone collector. The whole airflow system is a sealed circulation, and is circulated under positive and negative air pressure.

What are the advantages of Raymond Roller Grinding Mill Machine?

1. Small floor area

Raymond roller grinding mill machine is a three-dimensional structure with small floor area and strong systematicness. It can form an independent production system from rough processing of raw materials to transportation to pulverization and packaging.

2. Energy-saving

Electromagnetic vibration feeder is used for uniform feeding, easy adjustment, small volume, light weight, oil and electricity saving and convenient maintenance;

3. Stable performance

The transmission device of the machine adopts closed gearbox and pulley, with stable transmission and reliable operation;

4. Durable

The important parts of Raymond pulverizer are made of high-quality steel, and the wear-resistant parts are made of high-performance wear-resistant materials. The whole machine has high wear-resistant performance and reliable operation;

5. Easy maintenance

The blade holder of the main engine is always in contact with materials during operation, so the blade holder is composed of upper and lower parts. After the lower seat is worn, the connecting bolts can be removed and replaced;

6. Easy to adjust

Electromagnetic vibration feeder is used for uniform feeding, easy adjustment, small volume, light weight, oil and electricity saving and convenient maintenance;

7. Intelligent operation

The electrical system adopts centralized control, the grinding workshop can basically realize unmanned operation, and the maintenance is convenient;

8. Environment friendly

Small dust pollution and low noise.

Why choose Clirik?

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK’s professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

FAQ

Because there are different kinds of Raymond roller grinding mill machine, so our YGM series Raymond roller grinding mill has different prices, I need to ask you some details to send you the more suitable quotation:

1. Which kind of material are you going to grind?

(Dolomite; calcite; quartz; basalt; barite; feldspar; gravel; bentonite; gypsum; granite; coal; slag; pebble; others)

2. What’s the production capacity you want? How many tons or cubic meters per hour?

( > 100 TPH > 50 TPH > 30 TPH > 10 TH > 1 TPH < 1 TPH)

3. What’s the granularity of the final products you need?

(in milimeter, micron or mesh)

4. What’s the max input size of the material?

(In inch, centimeter or millimeter)

We will give you factory prices with full specification, so please leave us an inquiry to know more details about price and packaging, shipping and discount.