Made in China “kicked into” the World Cup!

Release Time:2022-11-24

2022 World Cup in Qatar

The 2022 Qatar World Cup group stage is in full swing. Although the Chinese men’s football team missed the game, the Chinese elements in the World Cup can still be seen everywhere like stars in the sky. From stadium construction to power supply, from referees inside the stadium to mascots outside the stadium… Made in China has provided strong support for the World Cup in Qatar.

This time Qatar spent more than 220 billion U.S. dollars on this World Cup. This is also the highest expenditure in previous World Cups. Not only does every venue have air conditioning and ventilation systems, Qatar even built a city for it.

As the Chinese elements in this World Cup, the first ones are the construction of the World Cup final venue Lusel Stadium by China Railway Construction, the construction of the solar photovoltaic power station by Power China, the sale of 1500 new energy buses by Yutong Company and Qatar contract, and the communication solutions, various peripheral products and decorations provided by Huawei for the stadium.

This is a symbol of China’s development. It also shows that Chinese manufacturing and Chinese construction are increasingly recognized and loved by people all over the world.

Why is Made in China more and more recognized?

1. Large production scale.

China’s scale of the manufacturing industry is basically factories everywhere, no matter which city it is in? Whether it is the front line or wireless, there are processing and manufacturing factories. The scale can be imagined, coupled with China’s vast territory and rich resources, making the The transformation of the ubiquitous, become a trump card of China’s trade.

2. A complete range of products.

China’s manufacturing industry is not only large scale, but also complete varieties, close to 100%. Whether it is large cars, construction industry supplies or small household goods, China can produce them in a short time because in any product, China has factories. Therefore, for foreigners who want to mass-produce a certain product, choosing China means choosing the whole industrial chain, because everything can be found and mass-produced in China.

3. Convenient transportation.

Unlike other countries, rail transport in China is not convenient. Now China’s rail transport has been extended in all directions, and can reach every industry, every city. Therefore, on the manufacturing side, there is great convenience in collecting raw materials and exporting products, which are unique to China and not available to other countries.

4. Good quality and low price.

Our labor production cost is very low, so our product unit price will be low, It is not because the price is low that we don’t pay attention to the quality of our products, and our quality is very good, so we are more and more recognized by the world.

Why does our product quality get better?

With the development of the times, we are inspired to change from Made in China to Created in China. This is a “root” change. We pursue product quality and pay attention to details, so we will control the product from the source.

All items are manufactured from a fine powder, so choosing a good mill is also crucial.

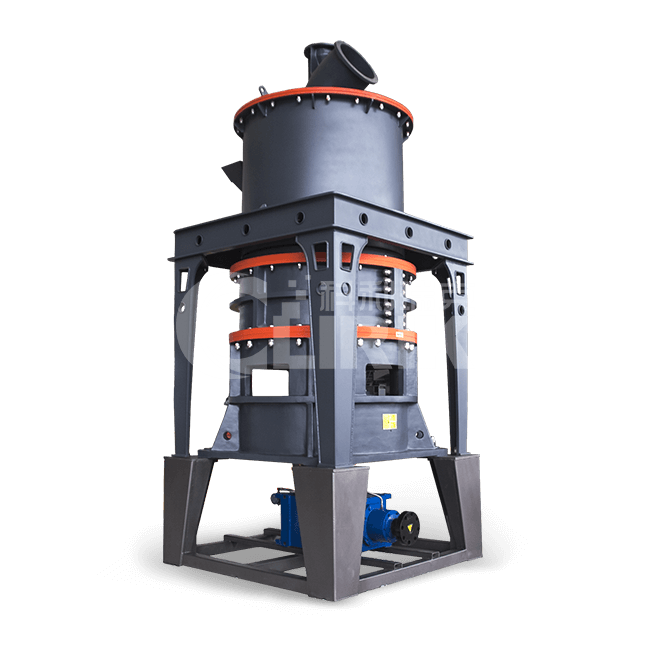

Clirik grinding mill

Processing ability: 1-45 t/h

Fineness: 150-2500 mesh

Max feeding size: 10-25mm

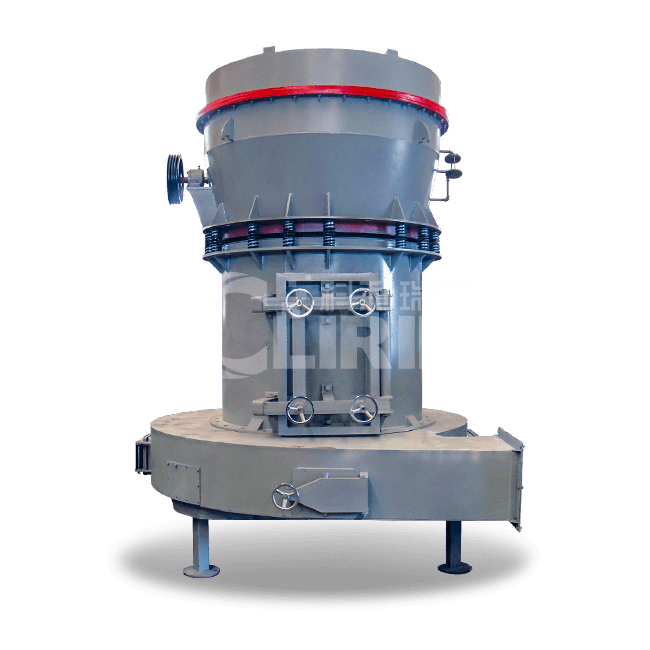

Processing ability: 1-20 T/H

Fineness: 150-3000 mesh

Max feeding size: <10 mm

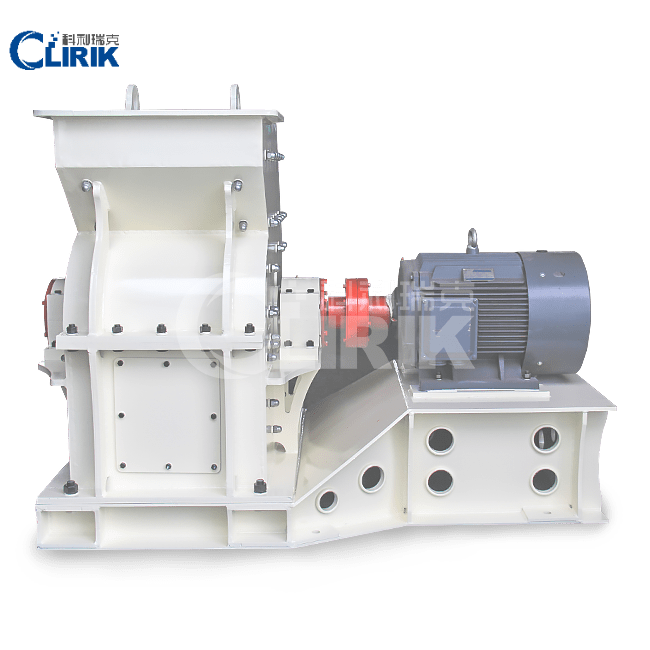

Processing ability: 1-35 t/h

Fineness: 80-500 mesh

Max feeding size: 35 mm

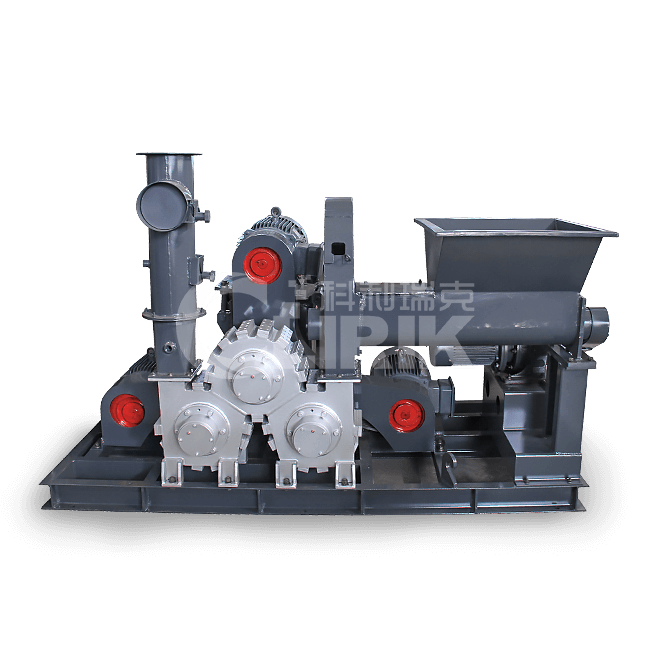

Processing ability: 1-30t/h

Fineness: 50-325 mesh

Max feeding size: 20mm

Processing ability: 5-30 t/h

Fineness: 0-25 mm

Max feeding size: <350 mm

It is suitable for modifying all kinds of ore powder and expanding its application field.