Gypsum powder processing equipment Raymond mill

Release Time:2023-01-05

Table of Contents

The gypsum powder Raymond mill is mainly used for the grinding operation of gypsum materials. This equipment is a relatively advanced grinding equipment in the field of grinding at present. It has the advantages of advanced structure, stable performance, and less maintenance.

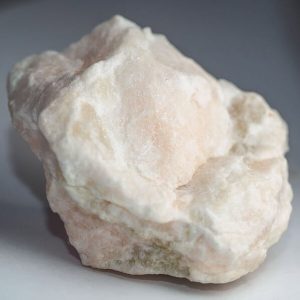

What is gypsum and its uses?

Gypsum is a monoclinic crystal system mineral, and its main chemical component is calcium sulfate (CaSO4) hydrate. gypsum is a widely used industrial and construction material. Can be used for cement retarder, gypsum building products, model making, medical food additives, sulfuric acid production, paper filler, paint filler, etc.

Gypsum stone ore can be crushed and ground by a gypsum industrial ultrafine powder mill machine to obtain gypsum powder. The crushed gypsum is processed differently according to different qualities and uses. High-quality, impurity-free gypsum powder can be used directly without heating and dehydration. It is “green gypsum”, which is mainly used in food, food, and chemical industries.

Gypsum powder processing process

The production process of gypsum powder can be basically divided into three stages: Crushing, Grinding and Calcination.

1. Crushing stage

The size and specifications of the gypsum ore are different after mining. According to the actual situation, the applicable crushing equipment is selected for preliminary crushing treatment, and the particle size is not more than 35mm.

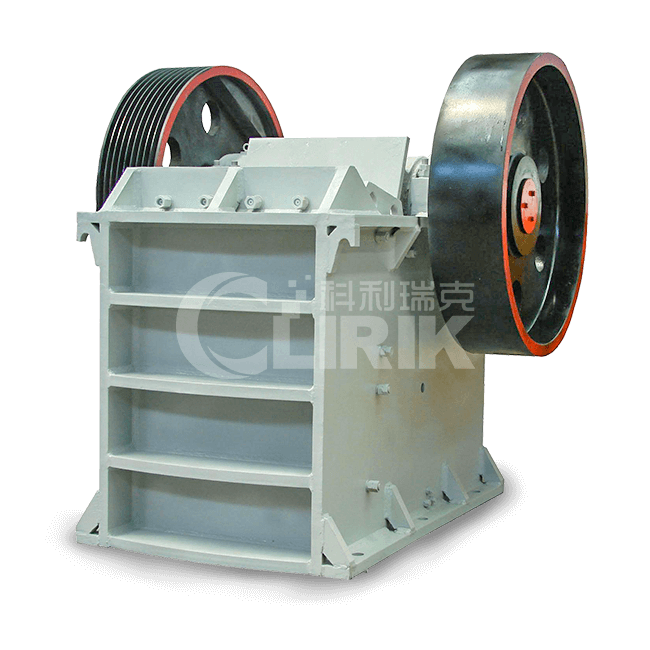

①. Jaw crusher

Jaw crusher fees particle size ≤1200mm, discharge particle size 10-350mm, the production capacity can reach 1-1000t/h. Suitable for rough crushing processing of large pieces of gypsum, crushing ability is strong, crushing ratio is large.

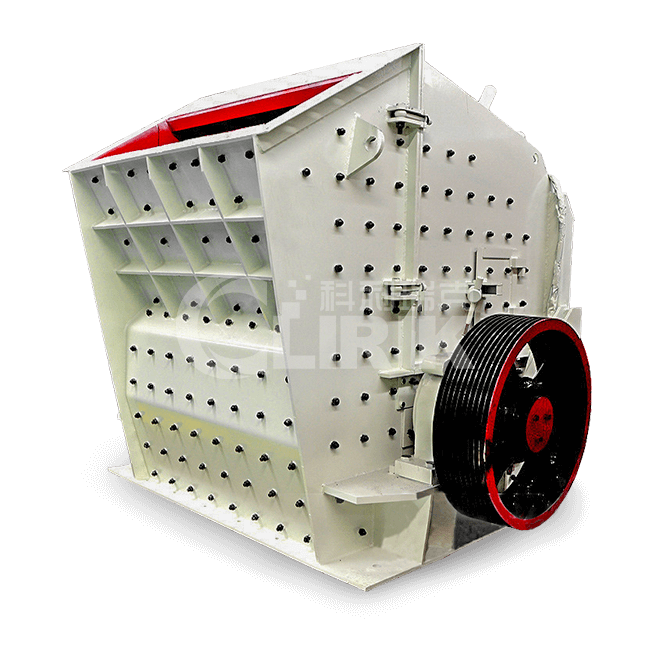

②. Impact crusher

Impact crusher feed particle size ≤1300mm, production capacity in 30-2000t/h, suitable for small hardness, Mohs hardness of 2-grade gypsum for medium fine crushing processing, and discharge particle type is very good, uniform particle size.

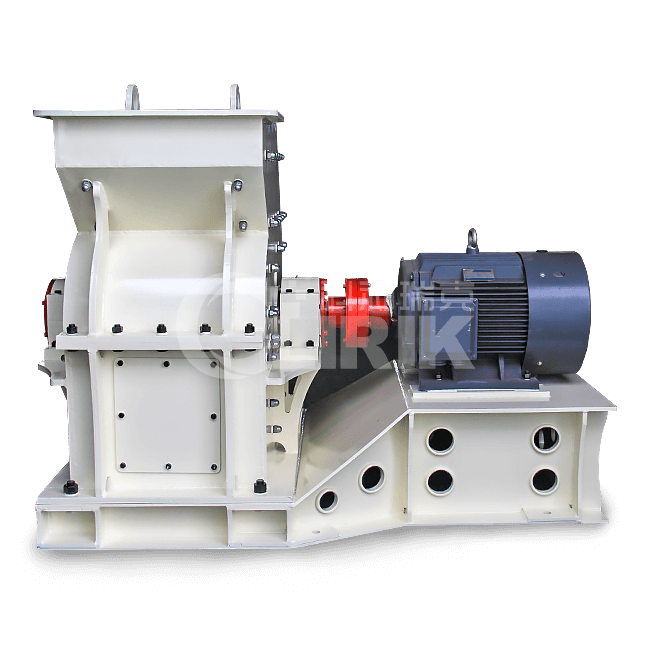

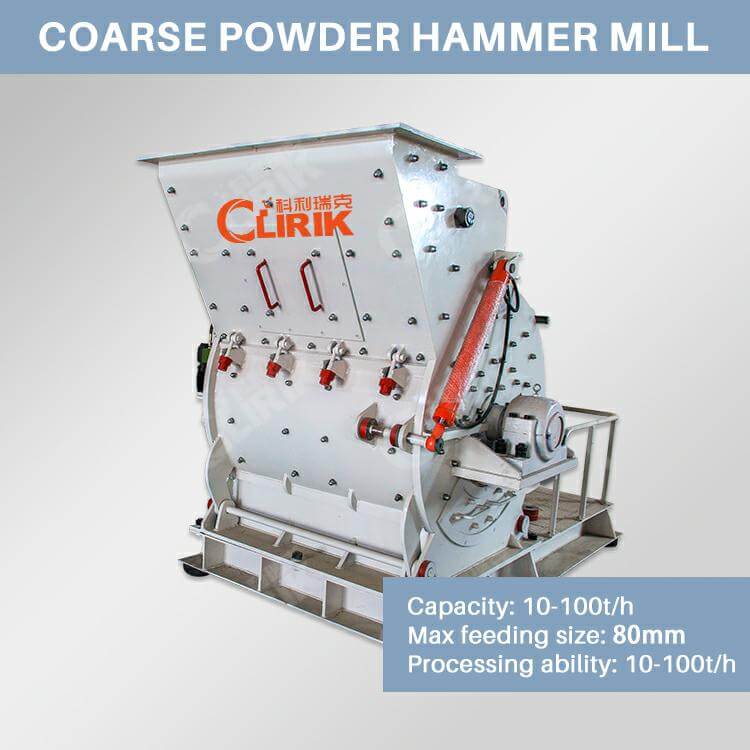

③. Hammer crusher

Hammer crusher is a crushing and forming crusher, suitable for crushing all kinds of medium hardness and brittle materials, feed particle size between 600-1200mm, production capacity is 160-1100t/h, finished product particle size is about 3-40mm, with large output, high efficiency, energy saving and low cost.

2. Grinding stage

The grinding link is the core link of gypsum powder production. After crushing, the gypsum is sent into the bin by the bucket elevator, and then evenly sent into the grinding machine by the electromagnetic feeder for grinding processing.

Gypsum powder Raymond mill

Gypsum grinding link is generally selected for gypsum powder Raymond mill processing operations. Raymond mill is good at high fineness grinding of non-flammable and explosive materials with Mohs hardness less than 9.3 and humidity less than 6%. The feed size of Raymond mill is ≤25-≤30mm, the discharge size is 0.044-0.173mm, and the class production is about 8-176t.

1.High pressure spring design

2.Smoothly vibration reduces design

3.Convenient vane adjust design

4.The machine has a strong material applicability, which suits many kinds of material whose Moh’s hardness is less than 6.

5.Grinding device adopts superimposed seal, sealed performance is good.

3. Calcination stage

After grinding is completed, the gypsum powder that meets the grinding standards is sent to the rotary kiln by the powder separator for calcining. The gypsum of Paris is sent to the storage warehouse by the elevator. The materials that do not meet the requirements are continued to be sent back to the grinding machine for grinding

Rotary kiln

Rotary kiln refers to the rotary calcining kiln, which is the equipment for calcining high grade cement in a cement factory. It is also widely used in metallurgy, ceramide, chemical, white ash, active lime and other industries. Red Star rotary kiln has large, medium and small options, with stable operation and high efficiency.

Parameter of Gypsum powder processing equipment Raymond mill

Clirik has many sizes of Gypsum powder processing equipment Raymond mill for you to choose from.

| Model | Roller | Ring | Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*1050 |

Advantage of Gypsum powder processing equipment Raymond mill

1. High Efficiency.

Gypsum powder processing equipment Raymond mill is a high-efficiency grinding machine that can grind various materials to the required fineness. It has a low energy consumption and can save more than 30% of energy compared to other grinding equipment.

2. High Output

The output of Gypsum powder processing equipment Raymond mill can reach up to 20-30 tons per hour, and the final powder size can be adjusted between 80-400 mesh. This makes it a popular choice for large-scale production of gypsum powder.

3. Wide Range of Applications.

Gypsum powder processing equipment Raymond mill can be used to process various materials, including limestone, calcite, barite, dolomite, marble, talc, gypsum, and other non-metallic minerals. It can also be used to grind materials in the fields of metallurgy, building materials, chemical industry, and mining.

4. Simple Operation.

Gypsum powder processing equipment Raymond mill is easy to operate and maintain, with a simple structure and reliable performance. The grinding roller and grinding ring are made of high-quality materials, which can ensure the long-term operation of the equipment.

5. Low Investment.

The Gypsum powder processing equipment Raymond mill has a low investment cost, and the operation and maintenance costs are also low. Therefore, it is an economical and practical choice for gypsum powder processing.

Why choose CLRIK’s Gypsum powder processing equipment Raymond mill?

1. Good reputation: We have a good reputation in the industry. Customers are very satisfied with our machines and services.

2. Professional knowledge: We are a professional manufacturer engaged in the production of mine grinding equipment for more than 20 years, and have rich experience in mine grinding.

3. Competitive price: We can not only provide you with cheap price, but also provide you with high-quality grinding equipment and service.

4. Flexibility: Our production line solutions can not only meet your basic needs, but we will also design a more sustainable development plan for you according to your industry development.

5. Product innovation: We invest a lot of money in research and development every year to develop products that are more suitable for customers.

If you would like to know more about this, please contact us click here. Leave us your requirements and your contact information, our sales manager will contact you later.

Other product recommendation

- Previous: Made in China “kicked into” the World Cup!

- Next: 2023 Clirik Start Working