Gypsum Roller Crusher

Table of Contents

- 1 Product Overview Of Gypsum Roller Crusher

- 2 Product Parameter Of Gypsum Roller Crusher

- 3 Working Principle Of Gypsum Roller Crusher

- 4 Product Parameter Of Gypsum Roller Crusher

- 5 Installation And Debugging Of Gypsum Roller Crusher

- 6 Maintenance Measures Of Gypsum Roller Crusher

- 7 Related Product Recommendation

- 8 FAQ

Product Overview Of Gypsum Roller Crusher

Gypsum roller crusher is a kind of mining machinery, also known as gypsum powder double roller crusher. This machine is mainly used for crushing ore. The crusher has small volume, large crushing ratio (5-8), low noise, simple structure, convenient maintenance, uniform particle size of crushed material, low over crushing rate, convenient maintenance, sensitive overload protection, safe and reliable. Suitable for coal, metallurgy, mining, chemical industry, building materials and other industries, more suitable for large coal mines or coal preparation plant raw coal (containing gangue) crushing.

Gypsum roller crusher a roller crusher that uses two mutually rotating rollers to crush material. It is composed of a motor, bracket, fixed roller, movable roller and safety spring. The roller surface is mostly smooth, movable roller bearings can move along the frame, and a strong safety spring support. When a particularly hard object falls into the roller, the bearing can be disassembled and spit out the object. Before normal operation, the spacer should be used to adjust the gap between the two rolls to ensure the crushing ratio. Suitable for medium broken viscous stone.

Product Parameter Of Gypsum Roller Crusher

| Model | Capacity (t/h) | Motor Model | Power (kw) | Overall Dimensions | Weight (kg) |

|---|---|---|---|---|---|

| GF4PG-90 | 70~100 | Y2-250M-6 | 37×2=74 | 2100×2450×2000 | 16100 |

| PCL-750 | 45 | 45-90 | 1500/2500 | 25-55 | 2780*Φ1800*2700 |

| GF4PG-120 | 100~130 | Y2-280S-6 | 45×2=90 | 2100×2750×2000 | 18500 |

| GF4PG-150 | 140~160 | Y2-280M-6 | 55×2=110 | 2100×3000×2000 | 21000 |

| GF4PG-180 | 160~190 | Y2-315S-6 | 75×2=150 | 2500×3000×2400 | 25000 |

| GF4PG-200 | 180~220 | Y2-315S-6 | 75×2=150 | 2500×3100×2400 | 26500 |

| GF4PG-250 | 220~260 | Y2-315M-6 | 90×2=190 | 2500×3330×2400 | 28100 |

| GF4PG-300 | 260~310 | Y2-315L1-6 | 110×2=220 | 2500×3730×2400 | 31200 |

| GF4PG-350 | 300~360 | Y2-315S-6 | 110×2=220 | 2500×3860×2400 | 26500 |

| GF4PG-400 | 350~410 | Y2-315L2-6 | 132×2=264 | 2500×4160×2400 | 36500 |

| GF4PG-450 | 420~460 | Y2–355S-6 | 160×2=320 | 2500×4360×2400 | 40700 |

Working Principle Of Gypsum Roller Crusher

Gypsum roller crusher is mainly composed of a roller, roller supporting bearing, pressing and adjusting device and driving device.

Adjustment of gypsum powder to discharge particle size of roller crusher: With a wedge or gasket between the two roller adjustment device, adjusting bolt, wedge at the top of the device when the adjusting bolt will wedge pulled up, wedge rolling activity to the top from the fixed wheel, namely two roller clearance greatens, discharging granularity, when the wedge downward, activities under the action of the roller in a compression spring two rounds of smaller clearance, discharge size smaller. The gasket device adjusts the size of the discharge grain by increasing or decreasing the quantity or thickness of the gasket. When the gasket is increased, the gap between the two rollers becomes larger, and when the gasket is reduced, the gap between the two rollers becomes smaller, and the size of the discharge becomes smaller.

The driving mechanism is composed of two motors, which drive to the groove wheel through the triangle belt and drag the roller wheel, and rotate in the relative direction. When crushing the material, the material passes through the roller from the feed port, and is crushed by rolling, and the broken finished product is discharged from the bottom frame.

Product Parameter Of Gypsum Roller Crusher

1. The performance of gypsum roller crusher is reliable, the power consumption is small, the yield is higher than the force. And the pressing force of the scraper can be adjusted, and the roller machine is equipped with a roller grinder to repair the roller surface in time, and its disassembly is also very convenient.

2. Most gypsum roller crushers are equipped with a buffer device and scraper device, which can cover the sound of equipment. The main function is to clean the material adhered to the surface of the roller.

3. The roller crusher is also provided with an overload protection device. The two rollers on the machine are respectively started by two motors, the tension is formed in the leisure between the two rollers by continuous extrusion and broken.

4. The wear resistance and impact resistance of roller crusher are better, and the material is fed into the machine from the upper part, which destroys the equipment and has the role of plasticizing. can effectively guard iron and other hard objects into the roller machine, overload cover as usual, accept overload cover block, quiet pin, etc.

Installation And Debugging Of Gypsum Roller Crusher

Installation and Adjustment

Gypsum roller crusher is delivered by the main engine and spare parts. Before receiving the goods, check whether there is any damage, sliding parts, lubrication and rust on the machine, and whether there are any missing parts. After confirmation, install according to the installation instructions. In order to better withstand the average stress of the machine during work, the whole machine can be placed at the bottom of the frame to join the sleeper and leave the unloading position. After the installation is complete, strictly check whether the fastening part is loose.

A test run

1. No-load operation test:

The gypsum roller crusher shall operate continuously for not less than 2 hours after installation. When the machine is running, the bearing temperature rise shall not exceed 30℃, and the maximum temperature length shall not exceed 40℃. Sprocket, reducer, triangle wheel, roll rotation should be stable, no abnormal noise.

2. Load test:

The on-load operation test can be carried out on the basis of a good no-load operation test, and the on-load operation test time shall not be less than 8 hours of continuous operation.

Determine whether the actual output and output meet the requirements, and ensure that the bearing temperature rise does not exceed 35℃, the crusher should work smoothly, there should be no more violent vibration, and each fastener should be reliable. Each lubrication point must be filled with grease. Sealing should be good, no leakage phenomenon.

Maintenance Measures Of Gypsum Roller Crusher

1. No matter how to feed the gypsum roller crusher, it must be equipped with a reliable rust removal device to prevent other debris from entering the crusher.

2. Check the oil level of the main and auxiliary transmission gearboxes to ensure that there is enough oil supply.

3. The gypsum roller crusher must be started without load, and the residual materials in the crusher must be checked and removed before starting. Check the oil level of the main and auxiliary drive gearboxes to ensure adequate oil supply.

4. The gypsum roller crusher can start feeding if there is no abnormality after starting.

5. If the gypsum roll is crusher and stops for a long time or starts for the first time, the pulley should be rotated for 2-3 weeks in advance, and the motor should be used to “point” several times after confirming that the machine is running smoothly. When the motor turns in the right direction, the crusher can be officially started.

6. Regular spot check whether the particle size of grinding products of gypsum roller crusher meets the requirements. If necessary, the spacing between crushing rolls can be adjusted.

7. When the gypsum roller crusher stops normally, the feeding must be stopped in advance, and the machine can be stopped after all the materials in the standby machine are removed from the crusher.

8. The main and auxiliary transmission gear boxes of roller crusher are lubricated with gear oil. In summer and winter, the lubricating oil in the box should be replaced in time.

9. When changing the strength, particle size or crushing ratio of the crusher material, the nitrogen pressure of the buffer cylinder should be reset. The pressure should be appropriate to meet the compression force of crushing roller. Excessive compression force will accelerate the wear and power consumption of parts. Too small compression force will increase the superparticles of crushing products and make the moving crushing roller vibrate frequently. The nitrogen pressure of buffer cylinder is used in the range of 1.5-4MPa.

10. When reassembling the upper crushing roller and clamp shell coupling after maintenance, the round nuts and coupling bolts should be strictly controlled to tighten the torque. When tightening the bolts of the clamping shell coupling, attention should be paid to their sequence. Tighten the diagonal bolts first and then the middle bolts. At the same time, the clearance of the couplings on both sides of the end face should be even.

11. If the gearbox cover of the main and auxiliary gear boxes of the gypsum roller crusher needs to be opened for maintenance, the rubber seals must be replaced and reinstalled, and the static sealing surface is evenly coated with a layer of sealant to prevent the sealing surface from leaking oil.

12. The translational coupling bearings of the upper and lower parts of the crushing roller of gypsum roller crusher should be lubricated with grease. Design requirements should be used No. 2 or No. 3 calcium grease. Calcium grease should be injected once a week during normal production.

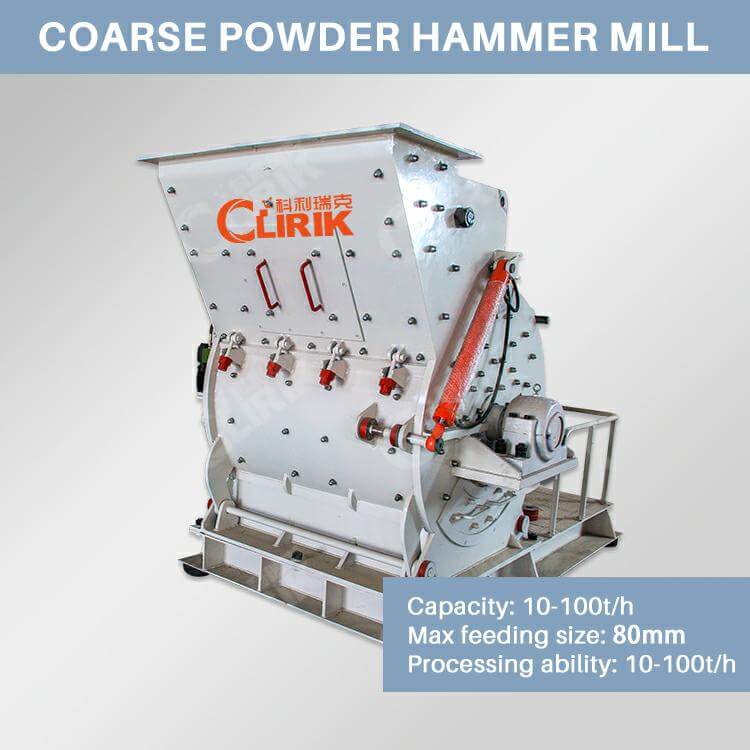

Related Product Recommendation

In addition to Gypsum Roller Crusher, Clirik also has many other crushing and grinding equipment, such as hammer crusher, jaw crusher, ultra-fine powder grinding mill, ultrafine vertical powder roller mill, high pressure suspension grinding mill, powder surface coating Machine, elevator, etc.

FAQ

1. Do you have an after-sales service?

All of our products have after-sales quality assurance services.

2. How long is your delivery time?

Generally, it is 10-15 days if the goods are in stock.

or it is 15-20 days if the goods are not in stock, it is according to quantity.

3. How to carry out transportation?

Express, sea transport, land transport, air transport, self – lift can be based on your needs.

4. What are the terms of payment?

L/C, Western Union, D/P, D/A, T/T, MoneyGram, Alibaba.com Pay, cash.

5. Are you a trading company or manufacturer?

We are a factory.

6. If I need an ores stone powder production line, can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We have already built many mining projects in China & overseas.